Improve Machinery Stability and Cut Maintenance Costs with Vibration Elimination

Zitat von Gast am 2. Februar 2025, 01:19 UhrMulcher Rotor Balancing: A Comprehensive Guide

In the modern agricultural landscape, ensuring the optimal performance of mulchers has become increasingly vital. Key to achieving this efficiency is the intricate process known as mulcher rotor balancing. This procedure involves the precise adjustment of rotor weights to minimize vibration, noise, and wear, thereby enhancing operational longevity and effectiveness.

Why Mulcher Rotor Balancing is Essential

When mulchers operate with imbalanced rotors, they not only produce excess vibrations and noise, but the strain can also lead to premature wear of bearings and increase the load on the drive system. Proper rotor balancing is essential to maintaining machinery health, reducing manufacturer costs associated with repairs and replacements, and ultimately extending the lifespan of the equipment.

The Fundamentals of Balancing

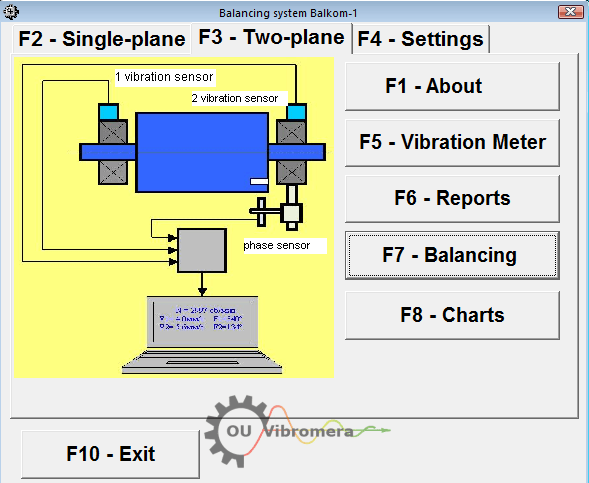

Using a portable balancer, such as the Balanset-1A device, allows operators to perform dynamic balancing on-site without dismantling the mulcher or extracting the rotor. This convenience enables timely adjustments and minimizes downtime, a crucial factor in agricultural efficiency.

Preparation Steps Before Balancing

The initial phase of the balancing process requires meticulous preparation. Operators need to conduct a comprehensive inspection of the mulcher. Critical checks include:

- Assessing bearings for any signs of play or wear.

- Inspecting the housing for cracks that may affect performance.

- Ensuring all bolted connections are secure.

- Deciding on the positioning or removal of the push frame and front curtain to avoid interference during the balancing process.

The Balancing Process

The process of balancing the mulcher rotor with the Balanset-1A follows clearly defined steps:

- Position vibration sensors perpendicular to the rotor’s axis of rotation and securely mount the tachometer on the magnetic stand.

- Apply reflective tape to either the pulley or the rotor to facilitate accurate data collection.

- Link the sensors to the Balanset device and connect it to a laptop.

- Launch the balancing software and select the two-plane balancing option, entering the rotor data required for accurate analysis.

- Measure the calibration weight and its mounting radius, and input these figures into the software.

- Start the rotor to gauge the initial vibration levels.

- Install a calibration weight in the first measurement plane, aligning it with the first sensor, and record the results.

- Relocate the weight to the second plane aligned with the second sensor for another measurement.

- Utilize the software’s analysis to determine the necessary adjustments, including how much weight to add and at what angle.

- Remove the calibration weight and install corrective weights as specified by the software.

- Conduct a final rotor spin to verify the effectiveness of the balancing process.

- Make additional adjustments as per the software recommendations to achieve optimal balancing.

The Balanset-1A: Your Essential Tool for Mulcher Rotor Balancing

The Balanset-1A Device is engineered to facilitate a seamless balancing process. The standard delivery set comprises various components, including:

- Control Interface Unit: The brain of the operation, processing sensory signals and managing the overall balancing task.

- Vibration Sensors: Two high-sensitivity sensors that measure vibrational parameters accurately, crucial for effective balancing.

- Optical Sensor (Laser Tachometer): This sensor measures rotor rotation frequency with outstanding accuracy and ease of use through its contactless reading capabilities.

- Magnetic Stand for Optical Sensor: A tool designed to ensure secure and precise positioning of the optical sensor throughout the balancing operation.

- Electronic Scales: These scales are vital for the accurate weighing of corrective weights, as precise measurements significantly influence the overall balancing quality.

- Specialized Software: The software provides a user-friendly interface for entering necessary parameters, analyzing data, and calculating the placement of corrective weights.

- Transportation Case: A robust case offered for the safe transport and storage of equipment, guarding it against potential damage.

The Future of Mulcher Rotor Balancing

As agricultural technologies evolve, so do the techniques for ensuring efficient operation and machine longevity. Emphasizing mulcher rotor balancing through advanced devices like the Balanset-1A will play a vital role in redefining agricultural practices. It addresses key challenges while promoting sustainable farming solutions by reducing vibrations and extending machine life.

Conclusion

In summary, mulcher rotor balancing is a crucial aspect that impacts the efficiency and longevity of agricultural machinery. By following a careful and systematic approach to balancing using modern tools such as the Balanset-1A, operators can significantly enhance their equipment's performance, reduce maintenance costs, and contribute to a more sustainable agricultural future. Investing time and resources in proper balancing ensures that your mulchers not only perform optimally but also stand the test of time in an ever-evolving industry.

http://wiki.die-karte-bitte.de/index.php?title=Fan_Balancing_Machine

https://kedarr914xgt0.blog2news.com/profile

https://thebookmarkfree.com/story16935834/vibromera-leading-in-balancing-and-vibration-analysis

Mulcher Rotor Balancing: A Comprehensive Guide

In the modern agricultural landscape, ensuring the optimal performance of mulchers has become increasingly vital. Key to achieving this efficiency is the intricate process known as mulcher rotor balancing. This procedure involves the precise adjustment of rotor weights to minimize vibration, noise, and wear, thereby enhancing operational longevity and effectiveness.

Why Mulcher Rotor Balancing is Essential

When mulchers operate with imbalanced rotors, they not only produce excess vibrations and noise, but the strain can also lead to premature wear of bearings and increase the load on the drive system. Proper rotor balancing is essential to maintaining machinery health, reducing manufacturer costs associated with repairs and replacements, and ultimately extending the lifespan of the equipment.

The Fundamentals of Balancing

Using a portable balancer, such as the Balanset-1A device, allows operators to perform dynamic balancing on-site without dismantling the mulcher or extracting the rotor. This convenience enables timely adjustments and minimizes downtime, a crucial factor in agricultural efficiency.

Preparation Steps Before Balancing

The initial phase of the balancing process requires meticulous preparation. Operators need to conduct a comprehensive inspection of the mulcher. Critical checks include:

- Assessing bearings for any signs of play or wear.

- Inspecting the housing for cracks that may affect performance.

- Ensuring all bolted connections are secure.

- Deciding on the positioning or removal of the push frame and front curtain to avoid interference during the balancing process.

The Balancing Process

The process of balancing the mulcher rotor with the Balanset-1A follows clearly defined steps:

- Position vibration sensors perpendicular to the rotor’s axis of rotation and securely mount the tachometer on the magnetic stand.

- Apply reflective tape to either the pulley or the rotor to facilitate accurate data collection.

- Link the sensors to the Balanset device and connect it to a laptop.

- Launch the balancing software and select the two-plane balancing option, entering the rotor data required for accurate analysis.

- Measure the calibration weight and its mounting radius, and input these figures into the software.

- Start the rotor to gauge the initial vibration levels.

- Install a calibration weight in the first measurement plane, aligning it with the first sensor, and record the results.

- Relocate the weight to the second plane aligned with the second sensor for another measurement.

- Utilize the software’s analysis to determine the necessary adjustments, including how much weight to add and at what angle.

- Remove the calibration weight and install corrective weights as specified by the software.

- Conduct a final rotor spin to verify the effectiveness of the balancing process.

- Make additional adjustments as per the software recommendations to achieve optimal balancing.

The Balanset-1A: Your Essential Tool for Mulcher Rotor Balancing

The Balanset-1A Device is engineered to facilitate a seamless balancing process. The standard delivery set comprises various components, including:

- Control Interface Unit: The brain of the operation, processing sensory signals and managing the overall balancing task.

- Vibration Sensors: Two high-sensitivity sensors that measure vibrational parameters accurately, crucial for effective balancing.

- Optical Sensor (Laser Tachometer): This sensor measures rotor rotation frequency with outstanding accuracy and ease of use through its contactless reading capabilities.

- Magnetic Stand for Optical Sensor: A tool designed to ensure secure and precise positioning of the optical sensor throughout the balancing operation.

- Electronic Scales: These scales are vital for the accurate weighing of corrective weights, as precise measurements significantly influence the overall balancing quality.

- Specialized Software: The software provides a user-friendly interface for entering necessary parameters, analyzing data, and calculating the placement of corrective weights.

- Transportation Case: A robust case offered for the safe transport and storage of equipment, guarding it against potential damage.

The Future of Mulcher Rotor Balancing

As agricultural technologies evolve, so do the techniques for ensuring efficient operation and machine longevity. Emphasizing mulcher rotor balancing through advanced devices like the Balanset-1A will play a vital role in redefining agricultural practices. It addresses key challenges while promoting sustainable farming solutions by reducing vibrations and extending machine life.

Conclusion

In summary, mulcher rotor balancing is a crucial aspect that impacts the efficiency and longevity of agricultural machinery. By following a careful and systematic approach to balancing using modern tools such as the Balanset-1A, operators can significantly enhance their equipment's performance, reduce maintenance costs, and contribute to a more sustainable agricultural future. Investing time and resources in proper balancing ensures that your mulchers not only perform optimally but also stand the test of time in an ever-evolving industry.

http://wiki.die-karte-bitte.de/index.php?title=Fan_Balancing_Machine

https://kedarr914xgt0.blog2news.com/profile

https://thebookmarkfree.com/story16935834/vibromera-leading-in-balancing-and-vibration-analysis